What is SandBlasting?

Sandblasting, also known as abrasive blasting or dustless blasting is a process done by blasting abrasives at high speeds to quickly remove contaminants off almost any surface. After sandblasting, the surface will be ready for a new paint job and renovation. Sandblasting is used on metal, brick, wood, concrete and other hard surfaces to smooth, clean, or for the removal of paint. Sandblasting has a similar effect as sandpaper but done at much higher speeds. Sandblasting is used by mechanics and machinery technicians because of its ease and accuracy.

The two types of Sandblasting are:

Water Driven Sandblasting

Air Driven Sandblasting

Both forms of sandblasting are great choices that end with similar results. The difference is the process of how the sandblasting process is completed. Water driven sandblasting also known as water blasting is most commonly used for rougher surfaces such as concrete or bricks. Air driven sandblasting is commonly used on metal surfaces such as cars and machinery. The abrasives used for sandblasting vary.

Sandblasting abrasives used Are:

Metal

Glass

Brick

Baking soda

Dry

Ice

Shells

The dustless sandblasting machine used at our shop uses a combination of both water and recycled abrasives. This combination has been able to show great success as shown in the Sandblasting before and after image below. This dustless sandblasting machine comes equipped with a rust inhibitor to prevent rusting for 72 hours after the sandblasting job is complete.

What Is Sandblasting Used for?

Removing Paint

Removing Rust

Removing old finish from a log

Removing Graffiti

Removes Primer

Removes Body Filler

Etching Concrete

Restoring Bricks

Dustless Sandblasting has many uses and can be used on many types material including metal, brick, wood, and concrete most commonly. A typical sandblast job is removing rust or paint from a car, boat, RV, or equipment leaving it ready for restoration.

Consider This Before Sandblasting:

Before doing any sandblasting job, you must make sure the correct abrasive is chosen, the size of abrasive, and ensure the pressure is set correctly depending on the type of job that is being done. Choosing the ideal combination can be tricky, so it’s always best to check with an experienced sandblasting technician. Another thing to consider is having the correct sandblasting gear or equipment for safety purposes.

Sandblasting equipment includes:

Safety Mask

Eye Goggles

Durable Gloves

Older clothing/Overalls/Body Suit

Ear Plugs

Tarp

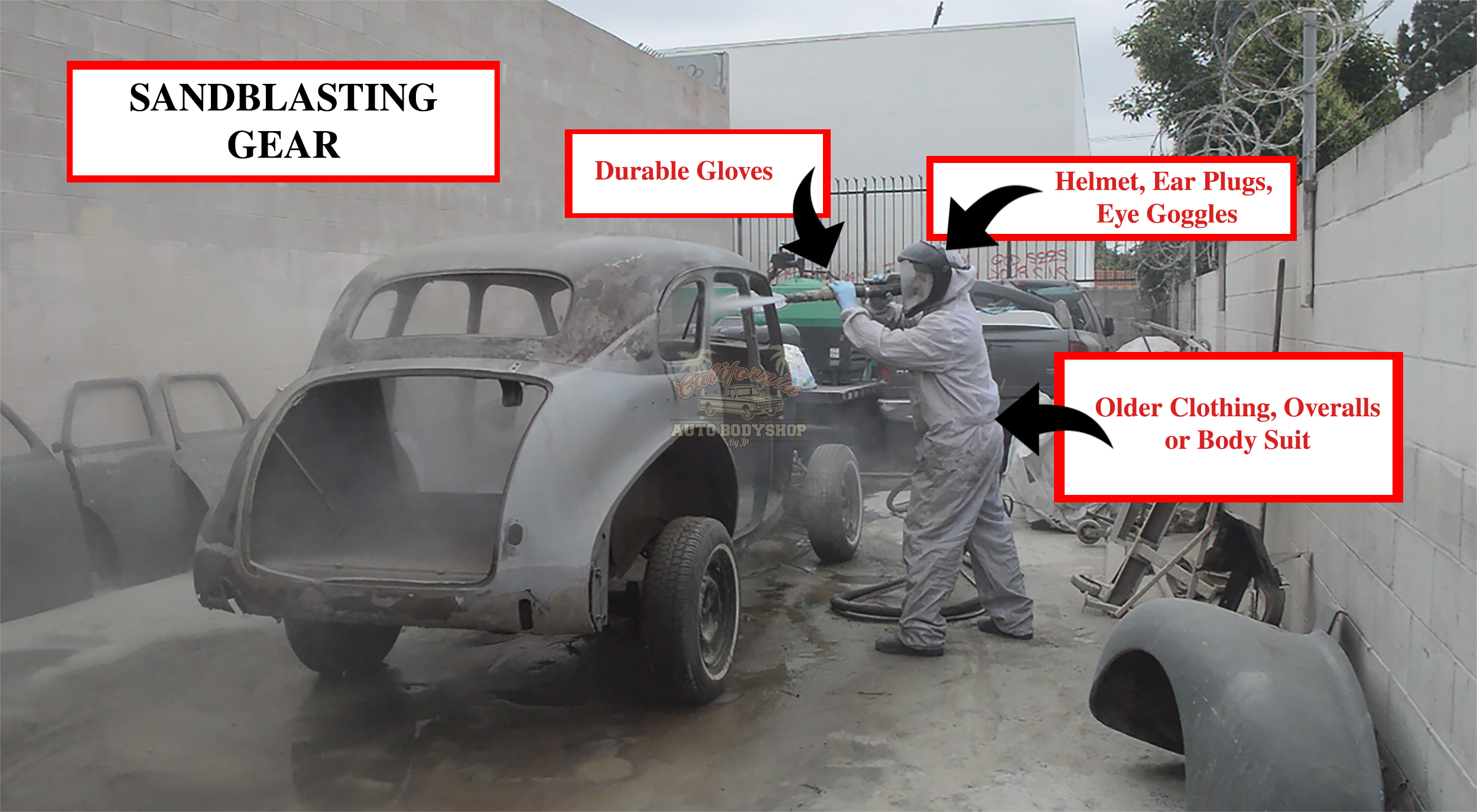

The following image illustrates the recommended sandblasting gear to wear during all sandblasting jobs to ensure safety:

During the sandblasting process, there will be abrasives and debris that repel off surfaces. A safety mask and goggle prevents any particles from entering your eyes or mouth. Durable gloves are also recommended because the sandblasting nozzle can get quite heavy after a while of blasting. Proper gloves ensure a good grip and overall control of the nozzle for optimal sandblasting. The process may get messy so wearing older clothing, overalls, or bodysuits are always best for this type of job. Ear plugs are also recommended because of the amounts of noise that is caused by the sandblasting process and the possibility of debris entering your ears. Lastly, a huge tarp would be great to consider. Laying tarp on the ground and surrounding areas makes clean up very easy. You can easily roll up the fallen debris and put it away to leave the working area clean.

For more information about Dustless Sandblasting contact The California Auto Body Shop or visit www.dustlessblasting.com for more information.